In today’s fast-paced and competitive oil and gas industry, maximizing efficiency through accurate data acquisition is paramount. With drilling operations becoming more complex and demanding, it is essential to have reliable custom molded cables that can withstand even the harshest environments.

Here are a few ways custom molded cables can help improve your oil and gas operations.

Enhanced Reliability and Durability

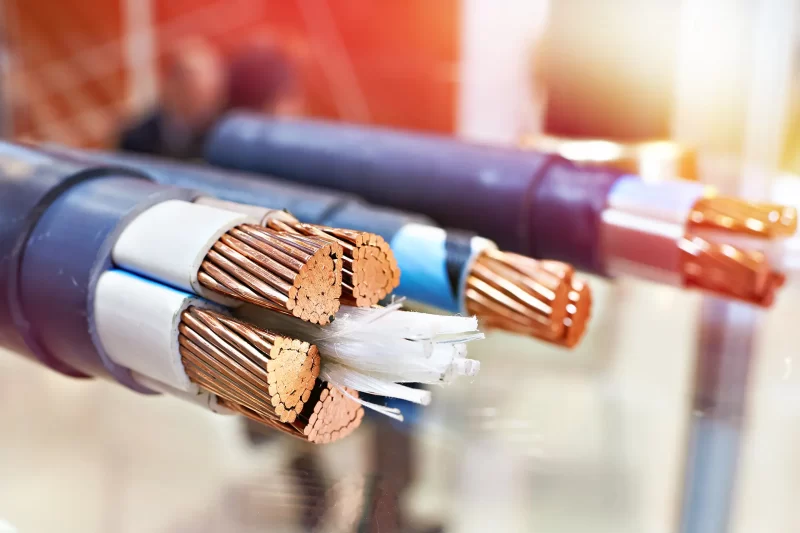

The standard off-the-shelf cables may not always meet the rigorous demands of your mining, fracking or drilling operations. Custom molded cables, on the other hand, are specifically designed and manufactured to withstand all sorts of extreme conditions such as high temperatures, pressure differentials, chemical exposure, and mechanical stress.

Engineered with superior materials and reinforced protection, these cables offer exceptional resistance to abrasion, oil, water, and other corrosive substances commonly encountered in the industry. They also ensure uninterrupted data transmission and overall operational efficiency by increasing reliability and reducing downtime due to cable failures.

Aesthetics

The overall look of any panel can be ruined by a connector that doesn’t match. A lot of connectors look quite industrial because appearance isn’t something most customers are concerned about when creating cable assemblies. They usually focus on creating a sleek and elegant look for their front panels.

The jacketing material of the molded cable assembly produces a result that matches the front of the panel and ensures that its elegance and sleekness will not be compromised.

Additionally, the custom molding allows branding to be incorporated into the molds. Which means you can add specific details such as company names and logos to the cable assembly as well.

Customization Options

One of the most important benefits of overmolded cable assemblies is the possibility of customization. Depending on your budget, the options available for material, wire type, style, and colour are endless. The mold is created to the specification of the client which makes the cable assembly essentially a custom product. You can also choose custom conductor types and jacketing materials. There is an added option of adding a molded connector which will create a stable and perfect fit for most equipment.

Optimal Signal Integrity

Accurate and timely data acquisition is critical for precise decision-making during drilling activities. Custom molded cables are carefully engineered to minimize interference and reduce the risk of data corruption or loss. By incorporating shielded conductors and precise impedance matching, these cables filter out electromagnetic interference (EMI) and radio frequency interference (RFI). This results in improved signal integrity, enabling drilling, mining and fracking personnel to make informed decisions based on high-quality data.

Custom Molded Cables for Tailored Design and Compatibility

All drilling, mining and fracking operations are unique, with specific requirements and equipment configurations. Custom-molded cables are perfect for all environments as they are designed and manufactured to fit seamlessly, regardless of conditions. These cables are customized in terms of length, connectors, and types of conductors to ensure optimal compatibility and ease of installation. Through minimized clutter and simplified connections, custom molded cables offer a streamlined setup, thereby reducing the risk of cable tangling or accidental disconnection. Moreover, with custom molded cables, there is no need for expensive and time-consuming modifications or adaptors – ideal for cost savings and improved operational efficiency.

Increased Safety and Hazard Mitigation

Safety is crucial in the oil and gas industry, where even the most minor problem can lead to significant consequences. Custom molded cables play a pivotal role in preventing potential accidents and hazards. Their rugged construction and insulation properties minimize the risk of electrical faults, short circuits, and fires, and they can be engineered to comply with industry-specific safety regulations to ensure optimal safety and reliability. In prioritizing hazard mitigation, companies can enhance their reputation while safeguarding both personnel and equipment.

In the oil and gas industry, precision and efficiency are vital for successful drilling, mining and fracking operations. Contact Instruments’ custom molded cables offer countless advantages, including enhanced reliability, durability, optimal signal integrity, tailored design, increased safety, and hazard mitigation. By investing in our tailor-made cable solutions, companies can greatly improve operational performance and reduce downtime while increasing profitability.